TSS testing measures the total concentration of suspended (non-soluble) solids in the aeration stabilization basin (ASB) or in effluents. The total suspended solids (TSS) data is critical in determining the operational behavior of a waste treatment system. It is usually a permitted test and solids must be kept at a minimum.

In order to test the total suspended solids, a well-mixed sample should be filtered through a weighed standard glass-fiber filter. The residue left on the filter is dried to a constant weight at a temperature between 103 °C and 105 °C. The increase in the weight of the filter represents the total suspended solids of the sample. Large floating particles or submerged agglomerates of nonhomogeneous materials from the sample may be excluded in the total suspended solids measurements if it is determined that their inclusion is not representative of the entire sample. The size of sampling should also be limited to a size that yields no more than 200 mg residue.

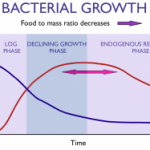

High total suspended solids (TSS) values in the effluent are often related to excessive solids generation due to an increase in BOD (Biochemical Oxygen Demand) loading or can indicate problems with the bacteria like nutrient deficiency. High TSS values can also be attributed to high flows or insufficient settling times due to quiescent zones becoming filled with solids. In aeration stabilization basins, high total suspended solids may indicate improper aeration within the system.

After the total suspended solids value is determined a volatile suspended solids (VSS) test may be performed in order to determine the concentration of volatile suspended solids in an aeration stabilization basin system. Volatile suspended solids data is critical in determining the operational behavior and biological concentration throughout the system. The filter used for total suspended solids (TSS) testing is ignited at 550 °C for 30 minutes. The weight loss on the ignition of the solids represents the volatile solids in the sample.