MLSS testing measures the total concentration of mixed liquor suspended (non-soluble) solids in the aeration basin of an activated sludge system. The mixed liquor suspended solids (MLSS) data is critical in determining the operational behavior and solids inventory. It is also used in determining sludge wasting and recycling rates.

MLSS testing measures the total concentration of mixed liquor suspended (non-soluble) solids in the aeration basin of an activated sludge system. The mixed liquor suspended solids (MLSS) data is critical in determining the operational behavior and solids inventory. It is also used in determining sludge wasting and recycling rates.

When testing the MLSS use a pre-weighted standard glass-fiber filter. The residue left on the filter is dried to a constant weight at temperatures between 103 °C and 105 °C

Choose a sample volume that will yield between 2.5 and 2000 mg after filtering.

The increased weight of the filter represents the MLSS of the sample. Large floating particles or submerged matter which is not representative of the entire sample should be excluded from the total suspended solids measurements. High mixed liquor suspended solids (MLSS) values in effluents are often related to excessive solids generation due to increased BOD (Biochemical Oxygen Demand) loading. High flow rates or insufficient settling times can also lead to elevated MLSS throughout a WWT system. As the MLSS concentration increases, higher nutrient and aeration demands are required to keep healthy biomass. However, an MLSS concentration that is too low can reduce BOD removal rates and disrupt settling during secondary clarification as a critical mass is essential in order to form a dense, uniform sludge blanket.

After the MLSS value is determined, a mixed liquor volatile suspended solids (MLVSS) test may be performed to determine the concentration of volatile suspended solids. The volatile solids remaining after the MLSS filter has been ignited to 550° C represent the biological portion of the suspended solids. This biological portion is considered the part of the MLSS that is responsible for BOD reduction. In some cases, fiber, cellulose, and other organic solids are included in the MLVSS. However, it is important to keep in mind these organic materials do not contribute to BOD removal.

In general, high MLVSS percentages are desired within an activated sludge system for effective BOD removal. When MLVSS percentages decrease below 80% in the aeration basin, it may be a sign that inert material is passing through after Primary Clarification. Proper maintenance of the Primary Clarifier can help reduce the undesirable buildup of inert material within the biomass.

Optimizing your MLSS/MLVSS to your plant’s typical BOD demand can help reduce costs from unnecessary aeration without sacrificing treatment performance. Bioaugmentation can help increase the density of desirable bacteria in the aeration basin when faced with low MLVSS percentages which in turn can help improve the removal rate of BOD across the system.

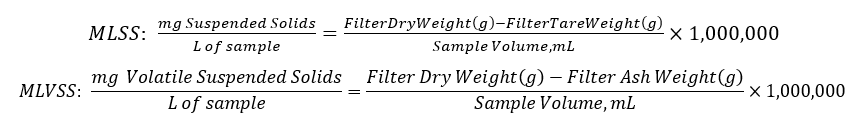

Calculations

For more information about our specialized blend of Bioaugmentation products or to speak with one of our Environmental Specialists about improving your wastewater treatment plant performance, please contact us.