Part 5 of 8: Retention Time and Flow Patterns

Time is the bacteria’s friend. Long retention times reduce the system’s dependence on bacterial reproduction and reduce nutrient requirements. Retention time is also critical so that log growth can be completed and endogenous respiration is reached. This allows the soluble Biochemical Oxygen Demand (BOD) conversion to be completed and floc formation to occur. Good floc formation leads to liquid – solids separation in the quiescent zone and low effluent total suspended solids.

Residence time theory is bounded by two extreme ideal flow situations: plug flow and complete mix flow. True plug flow is generally relevant to tubular equipment, and the fluid is assumed to travel through the system at a constant velocity so that every element of material gets processed the same length of time. In the case of complete mix flow, the assumption is that the concentration of a given attribute is the same throughout the system.

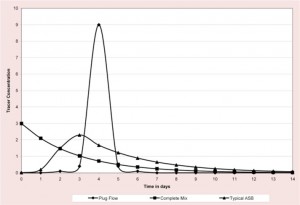

When the ideal plug flow or complete-mix flow assumption is not satisfied, the continuous flow system is said to be a non-ideal system. This means that the flow of fluid elements does not conform to the two idealized situations. In general, aeration lagoons would fall into the category of non-ideal flow systems, though some conform to plug flow conditions while others resemble a complete mix flow regime. The figure below shows a comparison of responses to the slug feed of tracer to a plug flow system, a complete mix flow system, and a typical non-ideal ASB.

Aeration Stabilization Basins (ASBs) are generally designed to exhibit both complete mix and plug flow characteristics. A proper balance is desired, since too much plug flow characteristic may not provide adequate equalization and true complete-mix may not provide adequate time under aeration for a portion of the stream.

An ASB differs from an activated sludge system in many ways. One of the most important, but least recognized differences is that ASBs constantly change, while an activated sludge plant essentially maintains its original capacity and configuration. By design, ASBs accumulate solids, resulting in a slow but steady reduction in system capacity and change in flow patterns. Con sequently, regular system surveys utilizing tracer studies, basin profiles, and sludge depth measurements are critical to ensure that the system is not allowed to reach the point at which it no longer is capable of providing the desired effluent quality.

Environmental Business Specialists can design a study for your system to determine retention time, the volume under aeration, % utilization, and flow patterns. These studies can provide valuable information needed to make sound technical decisions regarding such items as dredging, baffle placement, and aeration/mixing optimization.

This article is adapted from “Aerated Stabilization Basins in the Pulp and Paper Industry” by Paul Klopping and Mike Foster. 2003. Callan & Brooks. For information on purchasing a copy of this manual, contact EBS.